Robotmaster

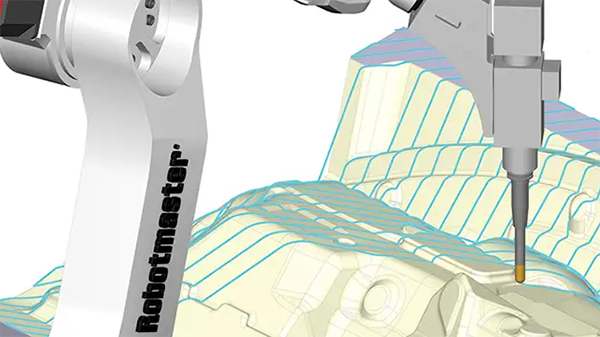

Robotmaster is an advanced offline software for programming industrial robots, belonging to the Hypertherm Associates family—an employee-owned company dedicated to industrial cutting technologies and solutions. Hypertherm Associates combines expertise in plasma, waterjet, and software solutions to help customers achieve unprecedented success. The development of Robotmaster began with the goal of demonstrating that CAD/CAM-based offline programming is key to productivity and quality in industrial robot programming.

Launched in 2002, the Robotmaster CAD/CAM robot software was immediately well-received by robot system integrators and manufacturers. This encouraged Robotmaster to expand the software’s functionality by leveraging expertise in CAD/CAM development, applied mathematics, and robot kinematics. Today, Robotmaster supports a wide variety of industrial robots and applications, including cutting, robotic machining, welding, grinding, painting, and many others.

The development of Robotmaster has gained acclaim and awards by making industrial robot programming fast, easy, and efficient. For example, it won the "Game Changer Award" in motion control at the 2013 RoboBusiness conference and was named in CIO Review magazine's list of the most promising robotics solution providers in 2015. Robotmaster joined the Hypertherm Associates family in the same year.

The Robotmaster team consists of researchers, developers, and engineers with diverse expertise, who are continually committed to innovation to enhance robotic solution performance and expand the capabilities of robots. The software integrates kinematics, mathematical optimization, and simulation algorithms to provide advanced solutions for various industries. Additionally, strategic partnerships with major robot manufacturers ensure seamless and state-of-the-art solutions for customers.

Robotmaster offers efficient and precise programming solutions for industrial robots in cutting, welding, surface finishing, and additive manufacturing. Its compatibility with different robot brands such as ABB, Fanuc, KUKA, and Universal Robots allows for easy integration of robots into various production environments. This enables businesses to improve production efficiency, reduce costs, and deliver high-quality end results quickly and effortlessly.

Robotmaster Homepage