Kemmler began collaborating with 5th Axis clamps

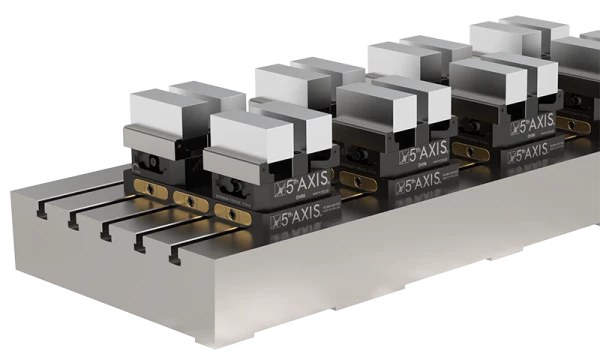

The German KEMMLER Präzisionswerkzeuge GmbH is known for its innovative, high-quality, and precise tool holders, which combine German quality with a competitive price. Kemmler's range also includes measuring instruments and various machine vices operated mechanically, pneumatically, or hydraulically. Kemmler's range of fastening solutions expanded significantly this autumn when Kemmler began collaborating with the American fixture tooling manufacturer 5th Axis.

Focused on innovative workpiece clamping solutions, 5th Axis was founded in 2004 in San Diego, California. The manufacturing processes and patented systems developed over the years have enabled 5th Axis's growth to remain efficient, competitive, and cost-effective as a fixture tooling manufacturer. The 5th Axis vises, which have gained great popularity worldwide, are familiar to many from industry YouTube videos and are also known as a partner of Mastercam. Now, all 5th Axis products are available directly from Kemmler's warehouse in Mössingen, Germany.

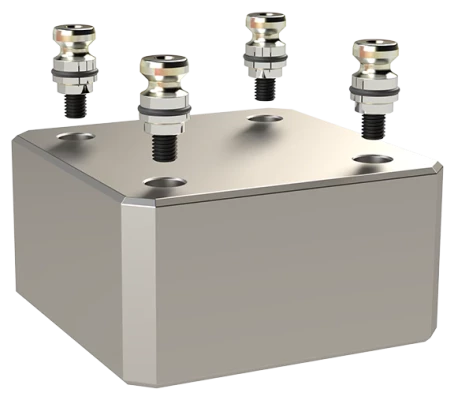

5th Axis products are suited, as the name suggests, for multi-axis machining, but they are also excellently usable with vertical and horizontal machining centers. 5th Axis vises can also be used in automated robotic cells with the pneumatic RockLock™ base plate. 5th Axis vises can be found in both self-centering and double vise models, with either hard jaws or machinable soft jaws. The 5th Axis vises are quickly and repeatably clamped to the RockLock™ base plate using their own pull studs. The 5th Axis vises' bolt pattern is designed to be compatible with the base plates of the most common equivalent vise models, using manufacturer-specific pull studs. The vises can also be attached directly to ready-made fixture towers or pyramids. The RockLock™ base plate allows for securing all other 5th Axis products to the same mounting platform. There are also 3D models available of all 5th Axis products, which facilitate their integration into CAM software.

5th Axis products are now also available in the Camcut product selection and they will be added to the webshop later this year.

DOWNLOAD THE 5th AXIS PRODUCT CATALOG HERE

Switch Vises and Fixtures Quickly

The standard clamping system allows for easy transfer of clamps from one machine to another without setup time

Precise

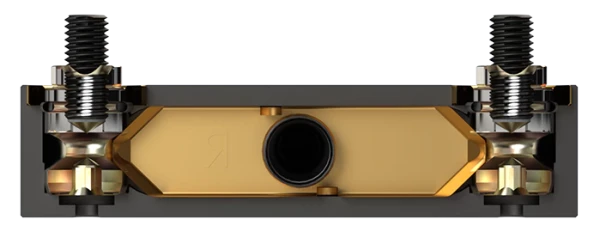

The patented Free Float design ensures the same clamping force on all four pull studs guaranteeing repeatability of less than 8 microns

Standardize Your Setup

No more building the workpiece clamp for every new job. Changing settings is easy with the RockLock system, saving you time and money.

Simplify Programming

Standard zero points speed up programming

Easy Integration

Pull studs are easy to integrate into existing clamps and base plates. The pull stud spacing of 52 mm and 96 mm ensures compatibility with competing systems.

User-Friendly

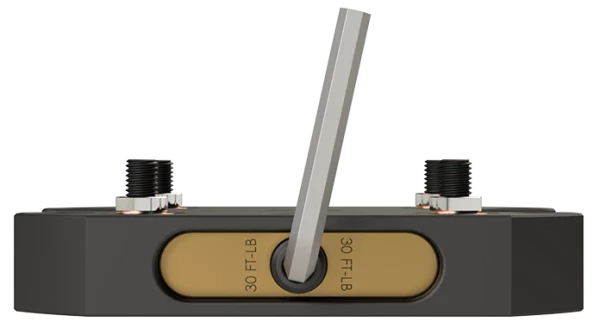

All clamping units are operated with a hex key from one side of the base plate, but access is available from both sides, eliminating the need to reach around the fixture.

Durable Construction

All RockLock base plates feature hardened steel rings and locking mechanisms. This ensures good repeat accuracy and wear resistance throughout the product's life.

Designed for Your Machine Tool

The RockLock range is designed with specific machine tools in mind. Be sure to specify the brand and model of the machine tool when ordering to get a perfectly fitting unit.