Mastercam 2024

Mastercam software celebrates its 40th anniversary this year! In 1983, two brothers, Mark and Jack Summers, conceived a new concept for programming CNC machine tools. A third brother, Brian Summers, soon joined them, and together they developed a computer-based CAD/CAM software that laid the foundation for the world's best-selling CAD/CAM software, Mastercam. Over the course of 40 years, Mastercam has developed dozens of new technologies for machine tools, such as hybrid machining, mill-turning, multi-axis machining, and patented tool paths utilizing dynamic motions, along with basic software packages for milling, turning, and wire EDM.

The software was initially named "Meghan" after Mark Summers' eldest daughter. It was later changed to "Mastercam" to more clearly describe the primary function of the software. Currently, Meghan serves as the company's CEO, and Mastercam is now the most widely used CAD/CAM software in the world.

User feedback helps drive innovation in Mastercam. Through its extensive collaboration network, Mastercam is constantly in touch with its customers, machine tool manufacturers like DMG Mori, Mazak, Makino, Okuma, Haas, Doosan, Tsugami, etc., and tool manufacturers such as Sandvik Coromant, Walter Tools, Seco Tools, Iscar, Kennametal, Emuge, etc., helping make Mastercam the most competitive CAM software tailored precisely to what machine shops need now and in the future.

Mastercam's new version, Mastercam 2024, includes numerous improvements to the user interface, 2D and 3D toolpaths, multi-axis machining, turning, and the Mill-Turn environment designed for programming multi-tasking machines. The new Mastercam 2024 has been released and is initially available only in the English version. The Finnish version will be released during August 2023 and delivered to customers through their respective resellers. Here are some new features of the new Mastercam 2024 version:

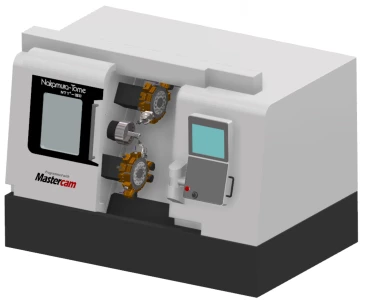

Mastercam Mill-Turn now also allows for importing adjustable angle heads into the machine simulation environment. Importing the adjustable angle head into Mastercam facilitates easy programming for angled rotating tools and reliable collision checking with the help of machine simulation.

The most notable visible change in the new version is the view control cube located in the lower left corner of the screen, which makes screen management even easier and more straightforward without having to remember keyboard shortcuts. The user interface has also been improved with a so-called "quick zoom" feature, which allows the screen to zoom at 7 times the usual speed, facilitating screen manipulation, especially with large workpieces.

The new hole handling feature significantly speeds up the machining of hole features in situations where multiple operations are performed on the same hole, such as center drilling, drilling, plunging, countersinking, and threading. Hole handling allows all the above-mentioned operations to be performed with a single function, making various hole operations quicker to program than ever before. The hole operations also have entirely new transition parameters, with display settings that make it possible to see different transition levels on the screen during operation creation. Transition levels can also be directly managed by clicking on the screen.

The new Mastercam 2024 version’s dynamic milling receives a new option aimed at maximizing tool contact with the material faster than in previous versions. With the "Maximize contact" option, the tool reaches the specified side shift more quickly, meaning that in alignments, thin walls, and complex shapes, there is no unnecessary motion in the tool path. This feature allows for significant machine time savings compared to previous versions of dynamic milling.

Mastercam 2024 facilitates the use of advanced tool paths now faster than ever with savable default parameters. The new version allows you to save and name multiple operation-specific default parameters so that when loading them, you only need to select the geometry to be machined and the tool to be used in the operation. Doesn't that sound both quick and easy? It truly is - the new Mastercam 2024 is a fast and efficient way to program a variety of machine tools using modern methods.

Download 10 highlights from the Mastercam 2024 version here

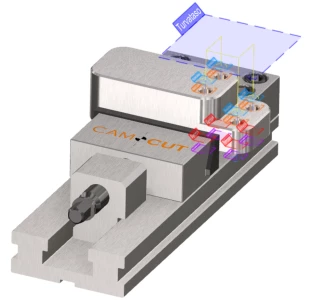

Camcut Oy actively organizes Mastercam training all over Finland. "Even a short training course can lead to significant savings when the software's features are fully utilized. Due to the new features, programming time shortens, and machining time and tool costs decrease," states Camcut Oy's trainer, Mikko Vepsäläinen. "New features are often not utilized, even if the latest software version is available, as users are usually accustomed to using certain types of tool paths," Mikko explains. In addition to CAM sales, training, and support services, Camcut also provides CAM programming services, combining decades of machining experience with Mastercam's powerful tool paths and the benefits of the latest tool innovations.