Walter Tools Product Innovations 2024-1

The German manufacturer of cutting tools, Walter Tools, has once again showcased its innovation capabilities by releasing a series of new products designed to meet the growing demands of industrial production regarding tool lifespan and productivity. The new tool offerings cover a wide range of products for turning, hole-making, threading, and milling, aiming to enhance both process reliability and efficient material removal. Walter Tools' new products also include expansions to existing product families. Below, we highlight some of the key new products.

For turning, Walter Tools introduces the tangential WT26 tool, designed to offer maximum productivity with long turning automatics. The WT26 tool uses precision-ground, sharp indexable inserts, ensuring high accuracy and longer tool life. The tool’s flexibility stands out in that all insert types of the WT26 series can be used in the same tool holder, reducing the need for multiple different tools. The range of tangential WT26 inserts includes solutions for rough and finish turning, grooving, and threading. The long cutting edge of the Walter WT26 turning tool allows for a thick chip thickness in situations where it is not possible to retract the bar blank back inside the collet chuck. The tangential clamping of the WT26 insert enables changing the insert without removing the tool holder from the long turning automatic. The insert screw can be opened and tightened from both sides of the tool holder.

The Walter Tools Xtra·tec® XT line's M5250 shoulder milling cutter is engineered to provide high process reliability and exceptionally high yet light-cutting metal removal in heavy machining. To achieve this, the tool combines a stable tool body with advanced insert geometry design. The M5250 shoulder mill guarantees cost-effective milling with the insert's four cutting edges. Compared to previous generation shoulder mills, the M5250 insert seats are designed for a radially negative position, which allows the tool to have larger chip pockets, making it more suitable for slot and ramp milling.

The previously introduced advanced Krato·tec™ coating technology extends to include X·treme Evo Plus solid carbide drills equipped with a 12 x Dc drilling length. The new X·treme Evo Plus drills, with longer drilling lengths, are coated with a unique Krato·tec™ coating from the drill tip and feature four guide lands. The X·treme Evo Plus drills are designed for universal use across all ISO material groups to maximize productivity with the help of Krato·tec™ technology.

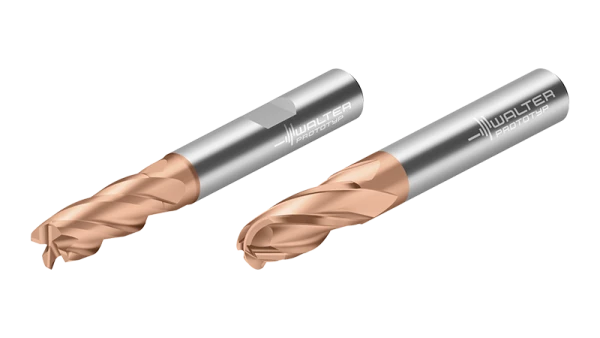

The Walter Perform Line product range offers everything needed for cost-effective milling. The ME232 Perform end mills introduce the new Perform HPC geometry, providing more stability to machining processes with its variable helix angle. The ME232 end mills are suitable for all ISO materials and support all common milling strategies. Additionally, the Perform product range expands with the ME432 Perform ball nose end mills, which offer excellent cost-effectiveness with their universal applicability.

DOWNLOAD WALTER TOOLS PRODUCT INNOVATIONS CATALOG HERE