Walter Tools Product Innovations 2025-1: New Solutions for Productivity and Process Reliability

Walter Tools continues its strong development work by releasing its innovative 2025-1 product line. The new products offer efficient and unique solutions for turning, hole making, threading, and milling. Expansions to existing product families and completely new technologies particularly support cost-effectiveness and process reliability in mass production. As the official distributor of Walter Tools, Camcut offers all new products in its online store with comprehensive technical information, real-time stock levels, and downloadable 3D models during the spring of 2025.

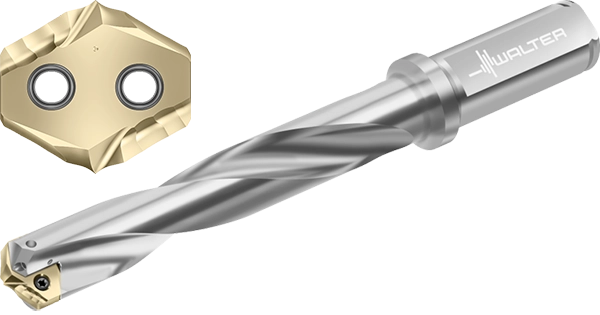

New Drion·tec® D-Spade – the world’s first exchangeable tip drill with a double-sided drill tip

The Drion·tec® D-Spade D5142 provides a completely new kind of cost efficiency for drilling operations. Thanks to the innovative double-sided drill tip, a single tip achieves two cutting edges, significantly extending the drill tip's lifespan and reducing costs. The symmetrical structure of the tip and four guidance ribs ensure excellent surface quality and process reliability, even with angled entry and exit points and intersecting holes. This new technology is particularly suitable for ISO P and K material groups.

New Walter F2252 disc milling cutter

The Xtra·tec® XT series disc-type slot milling cutter F2252 brings an innovative cassette structure to the market that allows for adjustment with an excentric screw and axial serrations. The new structure significantly increases the stability of the tool and the support of the cutting edge, allowing for higher feeds and better surface quality in groove and edge milling. The cassette solution uses popular BC-type indexable inserts, which are widely applicable across different materials and ensure versatility in production.

High process reliability with the Drivox·tec™ DD170 solid carbide drill

Walter Tools' new solid carbide drill DD170 Supreme offers extreme reliability for drilling. The drill is equipped with multiple guiding ribs placed peripherally, significantly reducing vibrations and ensuring precise hole positioning without pre-drilling up to depths of 12xD. Thanks to the Krato·tec® coating, excellent wear resistance and long service life are achieved, especially in demanding conditions.

Expansions to the ConeFit milling system

Walter Tools expands its ConeFit milling system with new interchangeable heads from the MD340, MD070, MC430, and MC500 series. The MD340 offers extremely stable and vibration-free machining for ISO P materials thanks to its variable helix angle. The high-feed milling heads of the MD070 series stand out with their speed and efficiency in machining ISO M and S materials. The revamped MC500 profile milling cutters cover a wide range of chamfer angles, facilitating tool selection for various applications.

Expansions to the TC620 Supreme and TC645 Supreme thread milling product families

Walter is expanding its popular TC620 Supreme thread milling family with new models equipped with a staggered multi-row structure and unique DeVibe technology. This effectively reduces vibrations during machining and ensures excellent surface quality and dimensional accuracy. The TC645 Supreme Thrill·tec™ thread milling range has also been expanded. These drill-thread mills create a pilot hole, thread, and chamfer with a single tool, reducing tool changes and improving overall machining productivity.

Innovative Groov·tec™ GD parting-off tool

The Walter Groov·tec™ GD parting-off tool receives new, even more efficient geometries (UE6 and RE6). These new cutting geometries provide excellent chip control and low cutting forces in all turning operations. The patented GD26 double-sided serrated blade ensures a precise and stable attachment of the insert, allowing groove depths up to 33 mm and cutting up to 65 mm.

Expanded solutions for internal and external thread turning

Walter Tools now offers a comprehensive range of new thread turning inserts in its TS series. The T1221 and T1222 series tools provide additional efficiency, particularly for deep hole thread turning. Additionally, Walter Capto thread turning holders and a unique 45-degree angle Capto holder for B-axis multi-task machines are now available. The combination of multi-tooth inserts, geometries, and Tiger·tec® Gold coating ensures long service life and excellent chip control.

Expansions to Walter Tools' T271.. indexable thread mills

There have been significant expansions in Walter's multi-row indexable T271.. thread mills, including threading for inch-sized threads, which enables even more efficient and productive threading. The TTG coating technology provides top-class wear resistance and process security. The thread mills are widely suitable for various materials.

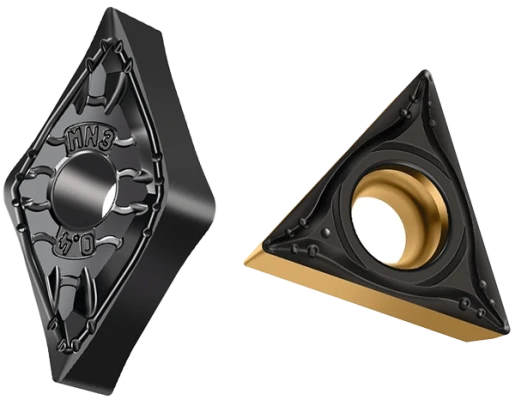

New ISO turning inserts

Walter introduces new ISO turning inserts, which offer high productivity and easy interchangeability for the most common turning tools on the market. The TCMT1103 WPP..G inserts with Tiger·tec® Gold coating offer excellent wear resistance. Additionally, the DNGG MN3-WNN10 geometries provide a competitive edge due to high positivity, double-sidedness, and good wear resistance, especially for ISO N material groups.

Learn more about the new Walter Tools 2025-1 products on the Camcut online store or contact Camcut's experts to take your machining process to the next level.