CloudNC CAM Assist

CloudNC's CAM Assist is the first AI-powered add-on for CAM systems. CAM Assist integrates directly into your CAM software, automating programming, maximizing your machine tool utilization, and boosting your business growth.

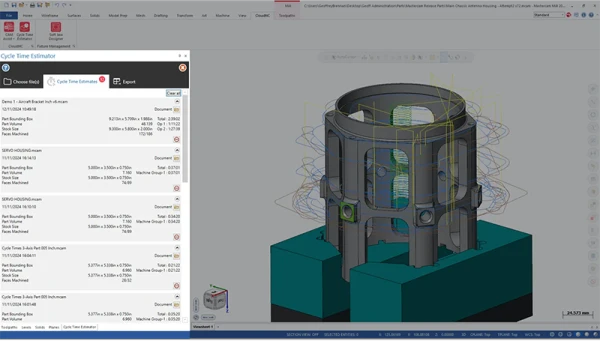

With CAM Assist, you can win more bids by processing over four times the number of quotes with machine time estimates. The AI understands your tools and machines, significantly speeding up the quotation process. Additionally, you can design fixtures in no time, creating customized soft jaws in seconds. This reduces the time spent on CAD design by an average of 40 minutes, freeing your programmers to focus on more productive work.

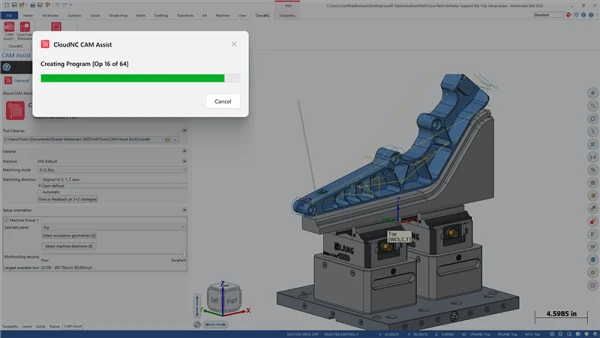

CAM Assist eliminates CAM bottlenecks, advancing your programmers to an 80% completion rate in program execution with just one click, multiplying their productivity. This AI solution also helps reduce material waste by providing AI-generated machining parameters. You can shorten the time from CAD design to the first machining by up to 80%, getting your machine tools up and running quickly and increasing productivity from day one.

CAM Assist operates by deeply understanding the rules and physics of machining. It generates countless ways to manufacture a component, considering unique combinations of your cutting tools, fixtures, and machine tools. This significantly speeds up production planning and reduces your manual workload.

Whereas feature-based machining identifies individual features and uses macros for repetition, CAM Assist leverages AI to manufacture the entire component. This means that CAM Assist can select the best tool paths and strategies for processing the entire workpiece, as it understands the part as a whole.

CloudNC CAM Assist integrates directly with Mastercam

CAM Assist is also available for Mastercam, meaning that even more machinists around the world can benefit from its productivity enhancements.

CAM Assist works with almost all CNC milling machines and retrieves your machine's parameters directly from your CAM package. The data is stored in accordance with GDPR. CAM Assist does not require new post-processing programs, and machining parameter management is conducted through a dynamic physics model that optimizes feeds and cutting speeds.

Contact us if you want to know more or acquire CloudNC's CAM Assist, so you can start benefiting from this innovative tool and save programming time immediately.