Mastercam Deburr

Mastercam Deburr is an Effective Solution for Deburring

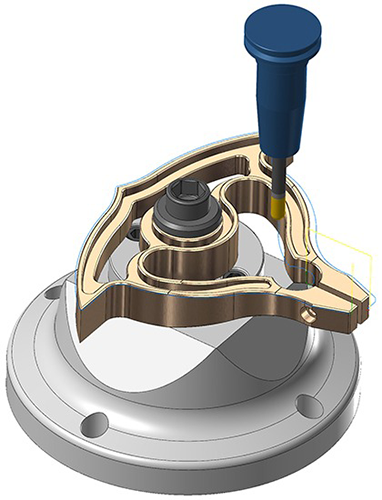

Mastercam Deburr is an add-on that brings the deburring operation, commonly seen in multi-axis paths, to 3-axis machining. It is available for Mastercam Mill, Mill3D, Router, and Mill-Turn licenses, offering users the ability to automatically remove burrs from the edges of Solid parts. This feature enhances machining quality and reduces the need for manual finishing, making it a valuable addition to production processes.

Mastercam Deburr simplifies deburring with automatic edge detection and user-friendly tools. It supports various tools such as ball-end and radius end mills, as well as tapered ball-end mills, allowing a wide range of machining strategies for both 3-axis and 3+2-axis methods. This add-on integrates seamlessly into an existing Mastercam setup and enhances the deburring process by connecting it directly to the machine, thus reducing processing time and improving overall efficiency.

With Mastercam Deburr, burrs produced during machining can be removed directly on the machine, improving productivity and reducing the need for manual finishing. The deburring function can also avoid specified geometries, like workpiece fixtures, ensuring uninterrupted machining. This reduces processing times, lowers costs, and significantly improves the quality of finished parts.

Deburring is crucial for maintaining the quality and safety of machining processes. Burrs can interfere with machining, affect workpiece re-clamping, and deteriorate the quality of the finish. Mastercam's Deburr add-on addresses these challenges, ensuring smoother operations and excellent final product surface quality. Available for Mastercam Mill 2D and 3D, Mastercam Router, and Mastercam Mill-Turn licenses, Deburr is easily accessible from the 3D machining path palette under finishing types or through Toolpath Management.

Overall, Mastercam Deburr is a pivotal add-on for machining workshops looking to enhance efficiency by reducing manual finishing work, lowering costs and processing times, and improving the quality of machined components.