Mastercam Multiaxis

Mastercam Multiaxis is a tool for programming complex machining paths

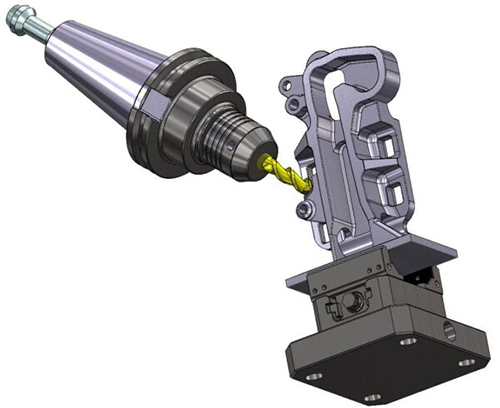

Mastercam Multiaxis is an excellent add-on for the Mastercam Mill3D software, providing users with the ability to program complex machining paths for simultaneous four and five-axis operations. This add-on utilizes cutting-edge technology to maximize the potential of machining tools by enabling movement on more than three axes simultaneously. This significantly expands the complexity and diversity of parts that can be manufactured. The Multiaxis program can be used with various machining centers, including lathes equipped with rotary tools and multitasking machines with a B-axis, making it a valuable tool for a wide range of manufacturing processes.

Mastercam Multiaxis offers a wide range of toolpath types, including advanced five-axis paths. Users can switch from one method to another effortlessly, adjusting the process as needed without losing efficiency or having to redefine geometry, collision checks, or transition parameters. Additionally, the software utilizes modern segment blade mills, allowing for the finishing of 3D surfaces up to 90% faster compared to traditional blade mills. This speed boost results in shorter production times and optimized processes, which are crucial in today's fast-paced manufacturing industry.

One of Mastercam Multiaxis's unique features is its fully automatic deburring function, which operates reliably in a variety of situations. Deburring can be performed efficiently and reliably using chamfer mills and side milling, speeding up the process and significantly reducing manual post-processing. This feature optimizes the production process and improves the quality of parts by reducing the risk of manufacturing errors.

The software also provides comprehensive collision checks and safety zone solutions to ensure safe toolpaths even in complex operations. Tool axis tilt limitations ensure that the tool does not dent the workpiece and allow for smooth machining events. In addition, Mastercam Multiaxis can be integrated with various platforms, including Mastercam Mill 3D, Mastercam Router 3D, and Mastercam Mill-Turn.

Mastercam Multiaxis is an essential tool for those looking to take advantage of the latest technology to enhance machining processes. It allows for the control of complex 4- and 5-axis toolpaths, improves production efficiency, and expands the variety of parts that can be manufactured. Whether producing complex parts, precisely machining 3D surfaces, or quickly removing burrs, Mastercam Multiaxis provides solutions to a wide range of manufacturing challenges.