VERICUT

VERICUT, developed by CGTech since 1988, is the world-leading NC code simulation software designed to enhance the efficiency, accuracy, and safety of CNC machining processes. VERICUT offers a wide range of products and solutions that prevent collisions in machine tools and significantly increase production efficiency.

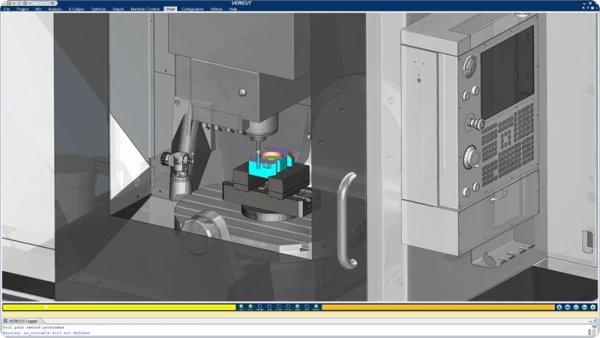

The VERICUT software simulates actual NC data on digital machines to make CNC production more efficient, competitive, and profitable. Collisions in CNC machining can be extremely costly, damaging machine tools and delaying production schedules. VERICUT can significantly prevent these errors, saving valuable production time from being wasted on testing new programs on physical machines.

VERICUT's CNC Machine Simulation detects collisions and near-miss situations between all machine components, such as rotating tables, spindles, tool changers, fixtures, workpieces, tools, and other user-defined objects. You can also define “near-miss zones” around components to check for such situations and detect machine movement over-travels.

Realistic Simulation and Broad Support of VERICUT

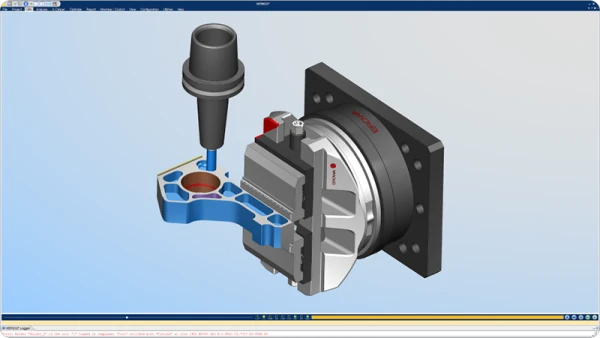

VERICUT enables realistic 3D simulation of entire CNC machines and provides the most accurate collision detection software available. It supports G-codes, multi-axis machining (milling, drilling, turning, grinding, EDM), and simultaneous tool operations with multiple spindles and workpieces. VERICUT also supports accessories like tailstocks, steady rests, part catchers, and bar feeders.

You can simulate both traditional 2- and 3-axis and multi-axis (4, 5, or more) CNC machines, such as DMG Mori, Grob, Soraluce, Hermle, Makino, Mazak, Okuma, Matsuura, Haas, and many more. The software supports multiple machine controls, including Heidenhain, Fanuc, Mazatrol, Yasnac, Siemens, and Fadal, etc.

VERICUT is independent of machine control, tooling, or CAM software and can be integrated with several leading CAM programs, such as Mastercam, Gibbscam, Siemens NX, hyperMILL, Surfcam, and Esprit. Additionally, it supports tool management systems like CoroPlus, TDM systems, and MachiningCloud, which allow you to easily import machining paths, tools, fixtures, and other elements into the machine simulation without manual specifications.

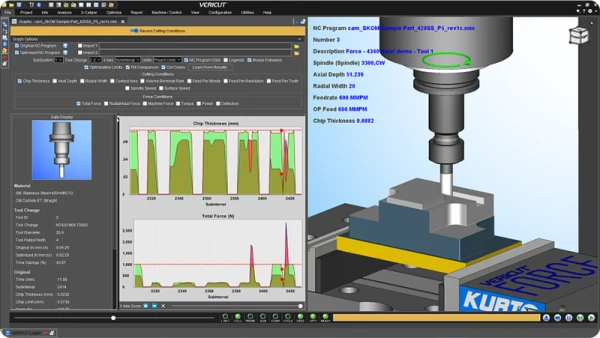

NC Program Optimization with VERICUT Force

VERICUT provides tools for optimizing machining programs, saving expensive machine time, reducing tooling costs, and extending the lifespan of machines. VERICUT Force is a physics-based optimization method that determines the maximum reliable feed rate under a specific cutting condition, based on four factors: cutter load, spindle power, maximum chip thickness, and the maximum allowable feed rate.

Force analyzes the properties of the material being machined, tool edge geometry, and cutting conditions, including the effects of friction and temperature. The analysis is based on actual cutting tests, ensuring accurate and reliable results.

Force machining optimization offers several advantages:

- Analysis for testing different machining scenarios

- Optimized chip thickness throughout the machining process

- Prevention of undesirable machining conditions, like excessive force, power demands, and tool deflection

Training and Support with VERICUT

VERICUT simulation allows for training without consuming expensive production time or risking machine collisions. The software gives operators clear and unambiguous instructions for new NC programs, improving machining efficiency and safety and enhancing documentation.

Camcut is the official distributor of VERICUT software. Known for comprehensive services, Camcut combines expertise in technical software with high-quality tools and services for chip-making workshops. With VERICUT software, we can provide our customers with an even higher quality software suite to improve production.

VERICUT is the world-leading NC machine simulation software that provides effective solutions for preventing and optimizing CNC machining errors. It realistically and accurately simulates and optimizes CNC machine tools, improving production processes, saving production costs, and increasing operational safety. The benefits offered by VERICUT make it an essential tool for modern manufacturing industries.

If you want to enhance your production efficiency and safety with VERICUT, contact Camcut and leverage the benefits of the world-leading CNC machine simulation software.