Walter Tools Product Innovations 2024-2: Innovative Solutions for Machining

German cutting tool manufacturer Walter Tools continues its strong path of innovation by releasing its new 2024-2 product line, designed to meet the industry's ever-growing demands for sustainability and productivity. The new products showcase a wide range of offerings for turning, threading, and milling, as well as tool holders, further enhancing the reliability of processes and the efficiency of material removal. This release also includes extensions to Walter Tools' already successful product families and introduces entirely new technologies.

Walter Tools products will soon be available in the Camcut online store, where you can explore detailed product and dimension information. In the online store, you'll also find product availability, download 3D models of tools and holders, and view customer-specific pricing information. Below, we present some highlights of the new products.

Longer Tool Life in Turning with Cermet

Cermet MP4 WEP10C represents the next generation of turning inserts offering excellent wear resistance for medium-hard machining tasks. The new medium-duty MP4 geometry enables the use of cermet inserts with chip thicknesses of 0.4-3.5mm. Its TiCN/CN-based cermet combined with Ni/Co binder and PVD TiCN/TiAlN coating doubles the tool’s service life. This makes it particularly suitable for machining steel, stainless steel, and cast iron without the need for complicated readjustments, maximizing dimensional accuracy and productivity.

New Walter Tools Groove∙tec™ Parting and Grooving Tool

The Groove∙tec™ G5011 is a new turning tool specifically designed for groove turning. Its precision cooling, combined with a toothed clamping mechanism on both the top and bottom, optimizes insert clamping and ensures stable groove turning even in dynamic turning. The uniqueness of the new insert clamping has led to a patent application. With the new GD26 insert technology, it is possible to machine grooves accurately and reliably up to 26 mm deep with widths of 2.5-6 mm, offering maximum productivity and long tool life. GD26 inserts are available in a wide range for parting, grooving, and profiling applications.

Innovative New Modular Walter Tools WE Series for Turning

Walter Tools presents the WE turning system based on exchangeable inserts. The WE system is optimized for machining small holes, grooves, and threads. The inserts are interchangeable, providing maximum flexibility and reducing setup time. The WE system, equipped with through-coolant channels, enables turning in internal diameters up to 7 mm and face machining up to 12 mm.

The Thread Turning Problem Solver

The new T1011 thread turning tool provides an excellent solution for machining external threads. The new TS thread turning inserts with Tiger-tec® Gold coating offer excellent cutting properties and longer tool life. Available insert geometries such as F5 and M5 are designed to improve chip breaking. The T1011 thread turning tool's carbide-coating side-supported insert seat holds the insert tightly and precisely in place while maintaining optimal fit. The TS thread turning insert range covers all common threads, including M, UN, UNJ, W, BSPT, NPT/NPTF, RD, TR, ACME, and BUTT, and they are now also available in a dual-insert box.

New High-Quality Walter Tools PCD Milling Cutters for Aluminum

Walter Tools has introduced a comprehensive range of new PCD milling cutters. The MP270 and MP271 PCD cutters with carbide shanks offer excellent stiffness and vibration control for precision machining. The MP470, on the other hand, represents the pinnacle of radius-end milling cutters, providing efficiency in complex shape milling. The innovative geometry of these PCD tools allows for the optimization of cutting forces, reducing vibration and enhancing tool longevity.

Extended Range of Walter Tools End Mills for Aluminum Milling

The MC Advance series of solid carbide end mills designed for aluminum machining is expanding with expected dimensions. The MC166 Advance is designed for finishing deep pockets and cavities as well as dynamic milling. Its three cutting edges achieve efficient material removal, which combined with spacious chip grooves, brings high process reliability in efficient material removal. The MC267 Advance is a multifunctional tool capable of performing roughing, semi-finishing, and finishing operations. It stands out particularly for its finishing capabilities in tight radius machining. The MC166 and MC267 end mill product families are now expanding with the anticipated corner radius-free end mill models. The MC467 Advance specializes in 3D shape machining, where precision and reliability are needed. Its ability to work in unmanned conditions makes it an attractive solution for the demands of modern industry.

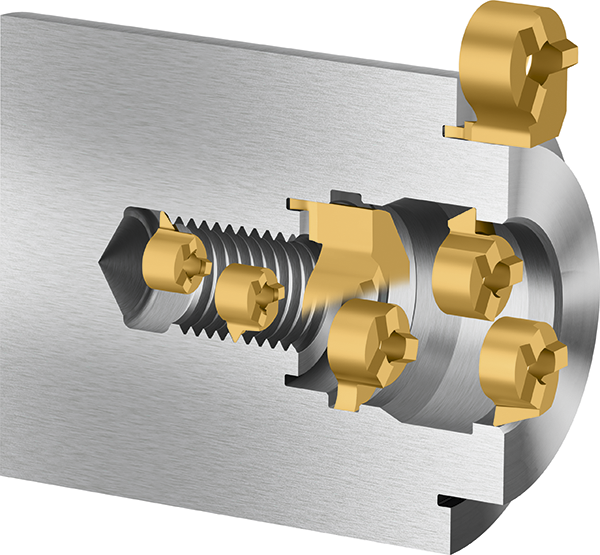

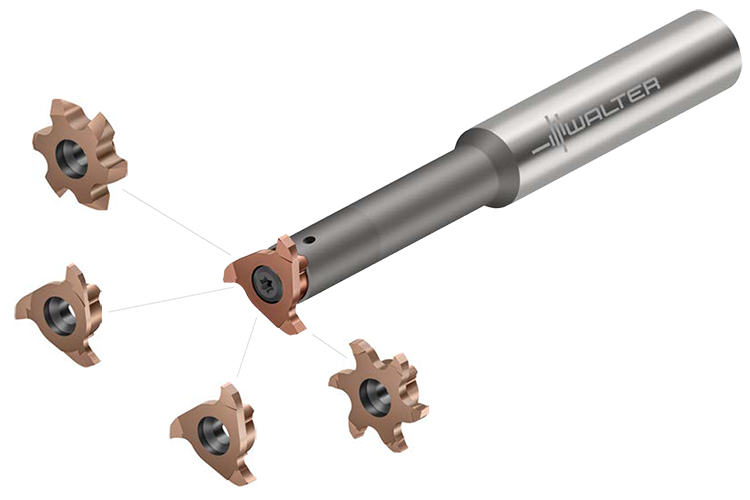

Modularity for Chamfer and Slot Milling

Walter Tools has unveiled a new milling family with changeable inserts, offering significant flexibility and versatility for slot and chamfer milling. In addition to the tool's steel bodies, carbide shanks with coolant channels ensure better cooling and efficiency. The interchangeable inserts, available in sizes from 6.7-39.7 mm and with three or six cutting edges, enable the machining of various slots and chamfers. This innovation is particularly suited for the machine shop industry for steels, stainless steels, cast iron, hardened steels, and difficult-to-machine ISO S group materials.

New Walter Thread·tec™ TD117 and TD217 Taps

The new Advance series Walter Thread·tec™ TD117 and TD217 taps bring versatility and excellent performance for both blind and through-thread production. The TD117 blind tap provides efficient threading for blind holes up to 2.5 × D depth. Its 40° helix angle and finished chip grooves ensure efficient chip evacuation, while the optimized cutting edge guarantees reliable threading. The TD217 through tap, in turn, is suitable for use with ISO materials up to 3 × D depth. Its improved clearance angle offers significant benefits in wear resistance and tool longevity. The new Thread·tec™ TD117 and TD217 tap coatings, WY80FC, WY80RG, and WY80AA, ensure broad applicability and performance for ISO P, M, K, and N material groups.

Renowned Walter TC620 and TC645 Thread Mills Expand Range

In thread milling, Walter Tools introduces extensions to the TC620 and TC645 thread mill ranges. The multi-row TC620 Supreme thread mills are known for their excellent tool life and vibration-free machining thanks to unique DeVibe technology, and they are now also available in 3 × D lengths.

The range of powerful drilling Thrill·tec™ TC645 Supreme thread mills now expands to cover larger M14-M20, UNC 9/16” - 3/4” and G1/2” threads. Drilling TC645 thread mills do not require a pre-thread hole, but a complete thread hole and its chamfer can be machined with one tool from start to finish to the chamfer. This frees up tool positions, e.g., with rotating tools in lathes, and reduces slow tool changes in machining centers equipped with large corner spindles. The TC645 is designed for both through and blind threads in ISO P, M, K, N, and S material groups up to 48 HRC hardness.

New Walter Tools Toolholders Enhance Machining Precision

Walter Tools has expanded its range of toolholders and adapters with several new products that offer flexibility, precision, and optimal torque transfer in various machining environments. Walter Capto™ toolholders C3-C8 support various milling types, and thanks to their modular design, they provide excellent durability and precision. HSK Monoblock adapters enhance the tool life and surface quality of machined parts, while SK Monoblock adapters and MAS-BT Monoblock adapters add value to machining due to their wide range of applications. Additionally, the new hydraulic and shrink holders enable even more precise and stable milling. With the new toolholders, Walter Tools meets the demanding needs of modern machining with a broader range of high-quality toolholders.

New products and technological innovations offer customers even better solutions to meet the most demanding needs of today's industry. A versatile range and the latest advanced materials ensure that Walter Tools can provide optimal durability, precision, and process efficiency in any machining environment. Thanks to these innovations, customers can improve their productivity and competitiveness in the market.

Walter Tools products will soon be easily available in the Camcut online store, guaranteeing customers effortless access to new solutions. Explore the new tools in more detail in the Camcut online store or contact our experts and take advantage of the opportunity to optimize machining processes with modern tool technologies.

[contact_member,name="",id=307,details=Name-Telephone-MobilePhone-Email]