Mastercam 2025: The new version of the leading CAM software has been released.

Mastercam, one of the world's leading CAD/CAM software, has released the highly anticipated Mastercam 2025 version! This version brings significant improvements and new features, making programming even easier, faster, and more efficient. We will provide new software version download links and updated postprocessors to maintenance customers during the fall.

We have just released a new training video product in our online store, where you can now purchase detailed step-by-step Finnish-language training on various aspects of the Mastercam software. The video training package you purchase can be viewed for one year from the purchase date. You can also share the viewing link with other users within your own organization. This way, everyone can study Mastercam easily and independently, anytime, anywhere. Explore our offerings and give yourself or your organization the opportunity to develop into a Mastercam expert easily and efficiently!

New Features of Mastercam 2025

Mastercam 2025 includes several new features and improvements designed to enhance the efficiency and accuracy of machining. These features significantly help save time and costs in the machining process while improving work quality.

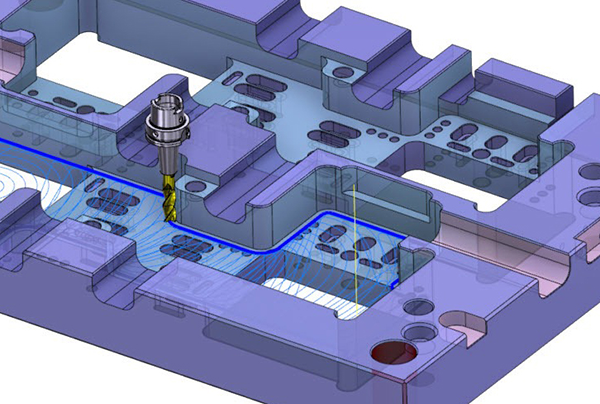

2D Dynamic Milling and Area Milling with Finishing Chips

One of the most anticipated improvements in the Mastercam 2025 version is the addition of 2D dynamic milling and area milling with finishing chips. Finishing chips allow for easy shaping with the same operation, saving programming time. This feature also enables preliminary finishing of the shape with machine tool control compensation, leaving the same machining allowance for actual finishing with sharpened tools.

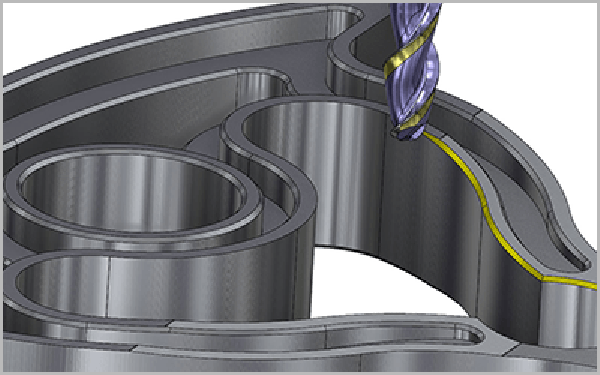

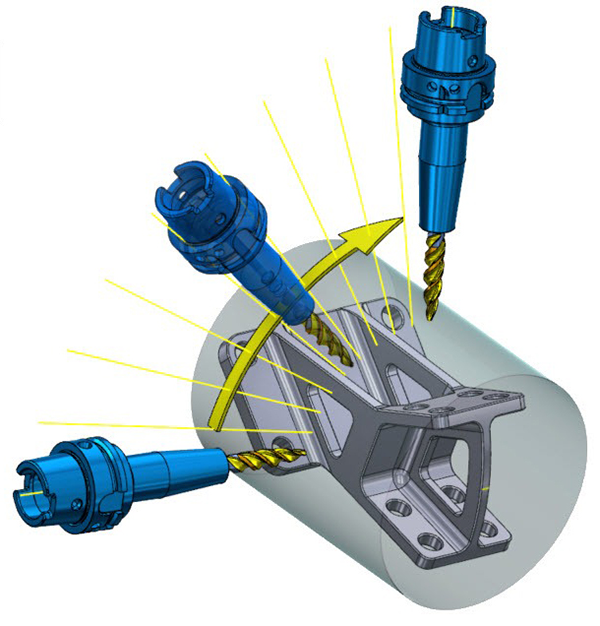

Fixture Geometry in 3D Operations

In Mastercam 2025, workpiece fixture geometry can be better accounted for in all 3D operations. This improvement reduces programming errors and prevents costly collisions on the machine, enhancing process reliability. Once defined, fixtures appear directly on the 'Model Geometry' tab of operations, making their management intuitive and convenient. This feature ensures that all fixtures and other important geometric elements are considered during programming.

Level Display Settings and Advanced Transition Parameters

The new advanced transition parameters in Mastercam 2025 allow better control over the heights of various machining levels, making them more visual and intuitive. Graphical level display settings enable transitions to be reviewed and edited directly on the screen, reducing design time and improving machining accuracy.

3-Axis Deburr Operation

The deburr operation, familiar from multi-axis paths, is now also available in Mastercam 2025 as a 3-axis version for Mill licenses as a Mastercam Deburr add-on feature. This feature automatically removes burrs from all edges of Solid parts, improving machining quality and reducing the need for manual finishing. The deburr function can also avoid defined geometries, such as workpiece fixtures.

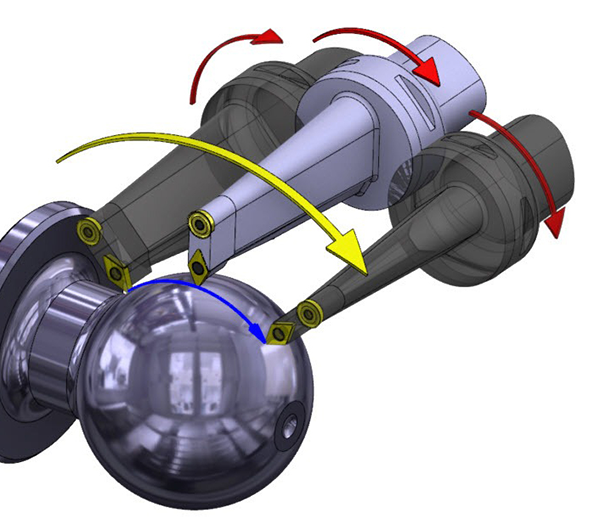

Y-axis Turning and A-axis Turning

Mastercam 2025 Mill-Turn now supports Y-axis turning in all traditional turning operations, as well as advanced operations like dynamic turning and PrimeTurning™. Y-axis turning is a highly stable method, as the cutting forces are primarily directed into the machine spindle during the process. In plunge and cut-off operations, the use of the Y-axis reduces the load on the cut-off blade, enabling the use of larger feeds and longer free lengths on the cut-off blades.

A-axis turning, which refers to Y-axis turning where the tool rotates around the tool axis (A-axis) during the turning path, is another significant new feature. This method allows for maintaining the tool's set angle consistently relative to the turned shape, enhancing process stability and chip control. Managing the A-axis during the turning process enables the turning of complex parts with a single tool and chip, without the intersections of different tools and operations.

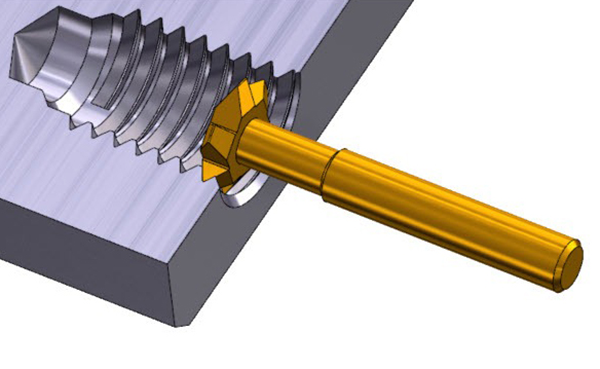

New Features of Thread Milling

Mastercam 2025 offers improvements in thread milling. New "Machining Direction" and "Spindle Direction" fields enhance the use of machining parameters. The "Straight Length" field allows for precise approach and exit movements, especially in the machining of small threaded holes. The "Incremental Approach/Exit" function improves tool life and accuracy by reducing tool wear. The "Tool Edge Feed Rate" calculates the peripheral feed rate for the thread mill based on the tool radius.

Hole Selection from Solid Models

Hole selection from solid models is now even more efficient in Mastercam 2025. Users can select holes directly from the solid model without model history, making hole operations smoother and faster. Hole machining functionality has improved selection rules and behavior and added new filters for the simultaneous selection of multiple holes, enhancing programming efficiency.

New Safety Zone Features in Hole Machining

The management of safety zones in hole machining has improved in Mastercam 2025. The new safety zone definition uses surface meshes for parametric forms, enhancing computation and management. New algorithms and parameters, such as linear tolerance, fitting distance, and smoothing distance, offer more precise control over tool movements, thereby improving the safety and accuracy of the entire machining process.

Mill-Turn Machine Configuration

In Mastercam 2025, Mill-Turn users can save and load machine configurations to improve efficiency. Configurations can be saved to separate files containing part and tool mounting components and easily loaded into later projects. The save and load buttons in job setup and tool settings enable flexible management.

Training and Online Learning Materials for Utilization of New Features

To effectively leverage the Mastercam software, users require knowledge and skills. We offer tailored training services that help machinists get the most out of the software's latest features. In addition to on-site training for customers, we now also offer Finnish-language Mastercam online learning materials in our online store, including videos and exercises. These enable self-paced learning of the software.

Camcut's training videos are designed to meet the needs of both the engineering industry and vocational institutions, providing comprehensive and in-depth self-study materials. Videos cover all key functions and features of Mastercam, including drawing workpieces, importing and creating fixtures and cutting tools, defining machining paths, and setting machining values. Training videos also include example files and necessary drawings, as well as 3D models that allow students to practice their learned skills in practice.

On the Camcut website's support section, you will also find descriptions and tips for all Mastercam machining paths and an professional glossary for use in machining shops. The professional glossary is a comprehensive knowledge base designed for machine shop professionals, such as machinists, that collects all key terms and concepts in the field into one place. It provides a clear and informative description of each term, helping both new and experienced professionals understand and use the correct terminology in their daily work.

[contact_member,name="",id=307,details=Name-Telephone-MobilePhone-Email]