Mastercam Lathe

Mastercam Lathe: Smooth and Efficient Programming for Lathes

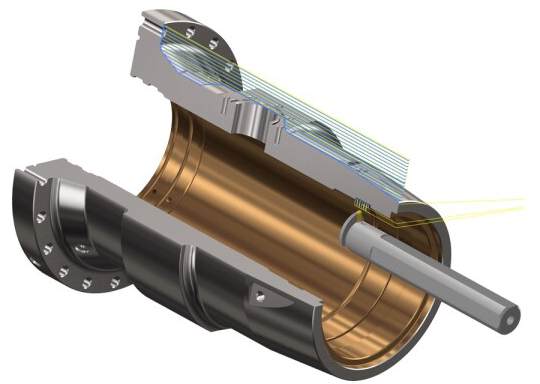

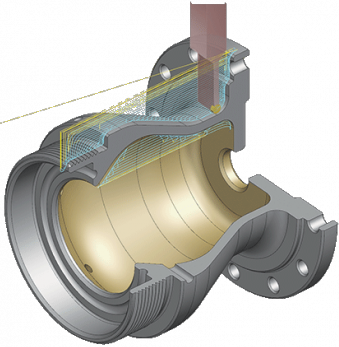

The Mastercam Lathe software enables the easy programming of turning toolpaths on 2D and 3D geometries with its advanced and versatile features. Using this software offers significant advantages over traditional lathe programming methods thanks to its latest toolpaths. With Mastercam, users can set toolpaths for variable chip thickness, chip breaking, intermittent turning, or tool inspection after every other chip, for example.

The evolution of technology in the field of turning has introduced an unprecedented level of versatility, efficiency, and precision. Thanks to its user-friendly nature, Mastercam Lathe clearly outperforms traditional methods. The interface allows for the design of toolpaths directly on 2D or 3D geometries or using advanced Mastercam Design features, making the turning of complex parts efficient and error-prone.

Advanced Turning Toolpaths with Mastercam Lathe

Mastercam's dynamic turning applies the same tool contact angle approach as dynamic milling. This unique technique allows for excellent chip management, ensuring a reliable machining process, especially when automation is high. Mastercam Lathe's dynamic toolpaths offer techniques that maximize material removal rates and reduce cycle times. The Dynamic Motion™ technology extends tool life and enhances machining efficiency.

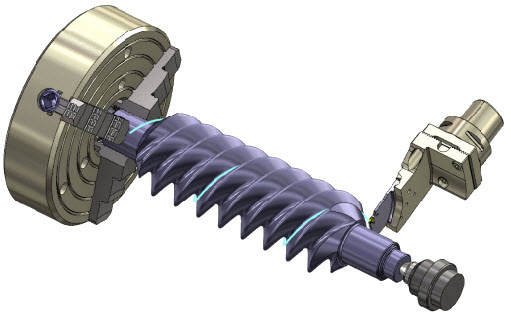

Mastercam also supports the turning of threads like rope threads using a single-point tool, eliminating the need for separate thread-cutting programs. All threading tasks can thus be easily programmed and simulated through the same interface.

Mastercam was a pioneer in the CAM software field by introducing PrimeTurning technology, developed in collaboration with Sandvik Coromant. This provides significant benefits in the turning of shaft-like components, especially in demanding materials, which not only speeds up production but also improves surface quality and extends tool life.

Ease and Innovation of Mastercam Lathe as Competitive Advantages

With Mastercam Lathe, existing machining operations can easily be reused by copying and importing from various sources, speeding up programming and significantly reducing the need for manual work. This saves time and streamlines the process.

Mastercam Lathe provides easy access to advanced programming tools and toolpath simulation. The software ensures machining accuracy and efficiency, whether you are a beginner or an experienced professional. With its diverse features, Mastercam Lathe significantly enhances manufacturing productivity and quality.

-

Mastercam Lathe