Mastercam Mill-Turn

Mastercam Mill-Turn: Advanced Programming Platform for Multi-Task Machines

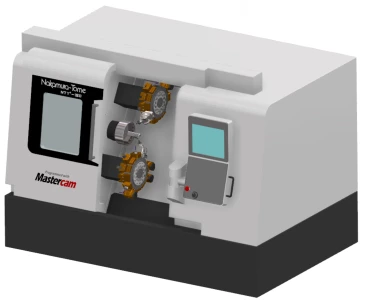

Mastercam Mill-Turn is a specialized software platform that efficiently combines the capabilities of Mastercam’s Mill and Lathe features for multi-task machines. The software facilitates advanced control over toolpath synchronization and collision checking in an advanced machine simulation environment.

Mastercam Mill-Turn simplifies the programming of multi-task machines, offering solutions to optimize, synchronize spindles and turrets, and simulate complex operations all in one platform. This software enables efficient milling, turning, and drilling with fewer setups and increased speed, while reducing the need for multiple manual interventions, repeated fixturing, and downtimes.

Key Features

- Synchronization and Optimization: Mastercam Mill-Turn provides a step-by-step setup of tasks that adapt precisely to your machine's requirements. It also offers intuitive, part-specific handling tools that help manage complex operations across different machining processes.

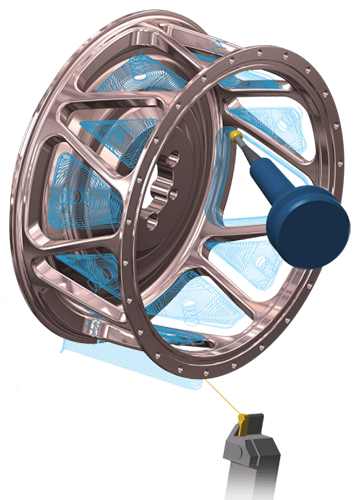

- Complete Machine Simulation: The software includes comprehensive machine simulation that provides accurate visual feedback. This helps verify potential collisions before sending the NC program to the machine, preventing costly errors.

- Customized Machining Environment for Multi-Task Machines: Machine configurations and their limits are graphically represented, ensuring safe and high-quality production.

- Advanced Toolpaths: Detection of collisions with stock, tools, and machine components before code is sent allows for clean, efficient, and precise programs for 3-, 4-, and 5-axis toolpaths.

Comprehensive Support of Mastercam Mill-Turn for Different Machine Environments

Mastercam Mill-Turn software offers comprehensive machine environments like Mazak Integrex, Okuma Multus, DMG Mori, CTX, and Nakamura-Tome. This ensures it is widely adaptable to diverse manufacturing situations and machining challenges. Additionally, the software leverages the Sandvik network, providing cutting-edge technology in the industry, such as PrimeTurning™ automated toolpath strategies and CoroTurn® tools.

Overall, Mastercam Mill-Turn is a vital tool redefining what is achievable in modern multi-task machine manufacturing, offering uninterrupted precision, efficiency, and reliability.

Advanced Technologies

- Dynamic Motion™: Maximizes material removal rates and reduces cycle times while extending tool life.

- Mastercam Code Expert: Optimized synchronization of machine movements between turrets and spindles generates precise and efficient code.

- Flexibility: Mastercam Mill-Turn offers complete programming capabilities and user-friendliness for twin-spindle, twin-turret, and B-axis lathes.