Mastercam Swiss

Mastercam Swiss: The Ultimate Programming Solution for Swiss-Type Lathes

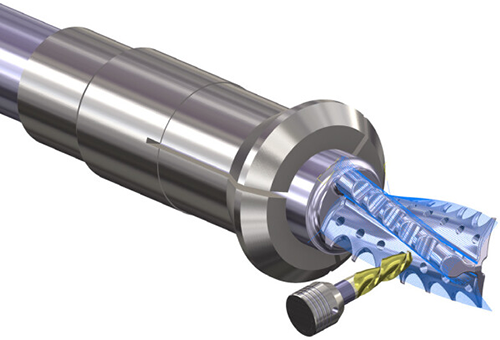

Mastercam Swiss is a top-tier programming environment specifically designed for programming Swiss-type lathes. The software combines Mastercam's Mill and Lathe features, enabling versatile toolpath programming from 2-axis to 5-axis parts. It provides users with a comprehensive toolkit for the most popular Swiss-type lathes, such as Star, Citizen, Tsugami, Swistek, Tornos, Hanwha, Ganesh, DMG MORI, Nexturn, among others.

Mastercam Swiss makes separate software packages a thing of the past for CNC Swiss machines, delighting many programmers and machinists. This software solution allows machine shops to standardize their production with a single software package and accurately and efficiently program a wide range of Swiss machines.

Mastercam Swiss offers precise G-code and flexibility to accommodate the needs of various Swiss-type lathes. The software includes customized Swiss synchronization settings to ensure accurate G-code programming and integrates CAD/CAM use, providing powerful tools for model creation and editing.

With Mastercam Swiss, users can take advantage of the Mastercam Lathe product for easy rough turning, grooving, thread turning, and drilling. Additionally, the software supports numerous milling operations, such as profiling, drilling, dynamic milling, etc., enhancing the productivity of rotating tools.

Key Features

- Efficiency: The software has tailored parameters for turning operation synchronizations, machine configurations, and user-defined options.

- Rotating Tool Use: C and Y-axis machining provides the ability to process any job with control.

- Versatile G-code: Synchronization codes allow for the creation of clean and tested G-code.

Advantages of Mastercam Swiss

- Dynamic Motion™: Maximizes material removal rates, extending tool life and reducing machining times.

- Powerful CAD: By opening any CAD file in Mastercam, CAM programmers can quickly select modeling and preparation tools and prepare parts for machining swiftly.

- Mastercam Swiss combines multiple programming features and offers a robust solution for various manufacturing needs, making it an indispensable toolset for the modern industry using Swiss-type lathes.