Mastercam Training

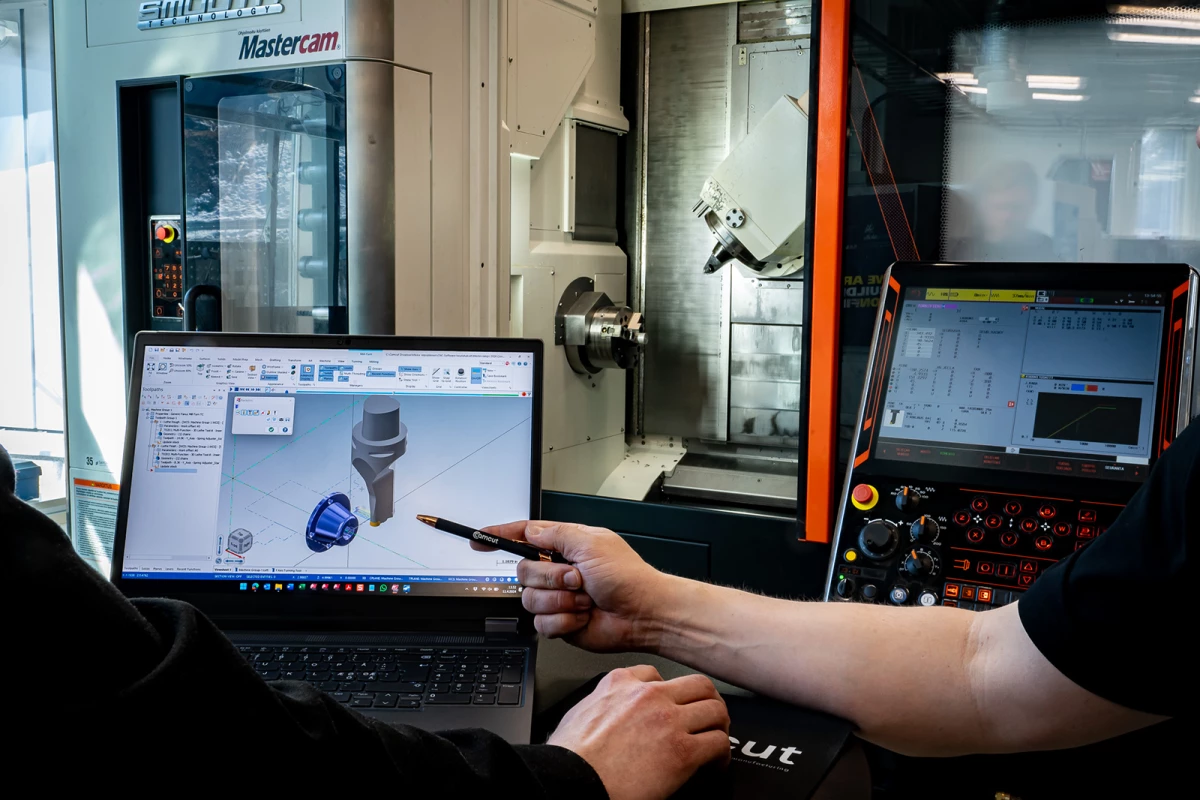

We offer Mastercam training tailored to the needs of both companies and educational institutions. The trainer's solid background in machining ensures a method-focused training that is easily comprehensible for machinists. We always customize our training according to the customer's needs, allowing for the implementation of method development for company products if necessary. With nearly 20 years of experience in corporate and educational training, we have successfully trained machinists who have excelled in competitions such as Taitaja and WorldSkills. Customizing Mastercam training to meet customer-specific needs is more crucial than ever in today's fast-paced and constantly evolving machining industry. To stay competitive, companies must stay updated on the latest machining techniques and methods. In this equation, the role of the right partner, like Camcut, becomes emphasized, as it not only offers Mastercam software training but also tailors it entirely to the customer's needs. This approach is key to enhanced production and improved productivity.

We offer Mastercam training tailored to the needs of both companies and educational institutions. The trainer's solid background in machining ensures a method-focused training that is easily comprehensible for machinists. We always customize our training according to the customer's needs, allowing for the implementation of method development for company products if necessary. With nearly 20 years of experience in corporate and educational training, we have successfully trained machinists who have excelled in competitions such as Taitaja and WorldSkills. Customizing Mastercam training to meet customer-specific needs is more crucial than ever in today's fast-paced and constantly evolving machining industry. To stay competitive, companies must stay updated on the latest machining techniques and methods. In this equation, the role of the right partner, like Camcut, becomes emphasized, as it not only offers Mastercam software training but also tailors it entirely to the customer's needs. This approach is key to enhanced production and improved productivity.

Method-Oriented Learning at Your Facilities

Typically, Mastercam training sessions are conducted on-site at the customer's facilities, focusing on method-oriented learning using the customer's own products. This practice allows trainees to directly see how the learned machining techniques and processes affect the efficiency and quality of their production. The result is a deeper understanding and better readiness to apply the acquired skills in practical work.

Technical Expertise Beyond Programming

Camcut is not just a provider of Mastercam software training. Its status as an official distributor of Walter Tools' cutting tools gives it unique technical expertise that extends far beyond basic programming skills. This means that Camcut not only teaches how to program machine tools with Mastercam but also provides in-depth knowledge of cutting tools, their proper usage, and the latest advanced machining methods.

Dynamic Machining – The Technology of the Future Here and Now

One of the most significant trends in metal machining is dynamic machining methods, such as dynamic milling and dynamic turning. Camcut trains its customers to optimally utilize these techniques. Dynamic toolpaths benefit from calculating the tool’s engagement angle with the material, optimizing toolpaths, enabling more efficient chip removal, and extending tool life. In turning, for example, the PrimeTurning™ method has revolutionized traditional turning by offering greater productivity and tool life.

Opportunities with Multi-Axis Machining

Modern manufacturing environments increasingly utilize multi-axis machining centers, which allow the creation of complex and precise parts in a single setup. Camcut's training covers how to effectively use tools like segment radius end mills in multi-axis machining to achieve better surface quality and machining speed.

Optimization of Toolpaths

By optimizing toolpaths, productivity can be maximized while minimizing tool wear and saving valuable machine time. Camcut's training emphasizes the importance of toolpath planning and teaches how to use the Mastercam software to achieve this critical goal. This includes planning toolpaths to ensure smooth and efficient machine movements while guaranteeing high-quality workpieces.

Continuous Development Path

Camcut’s training emphasizes continuous development and the adoption of new methods. The machining industry is constantly changing and evolving, and companies need to keep up with this development to maintain their competitiveness. Training does not stop at mastering the use of the Mastercam software; it opens doors to utilizing new machining strategies and techniques that can significantly improve production efficiency and quality.

Mastercam Training Tailored to Customer Needs

The Mastercam training offered by Camcut is much more than basic programming lessons. It is an in-depth dive into modern manufacturing techniques, machining methods, and tool optimization, all tailored to meet the customer's individual needs. This approach not only strengthens a company's ability to efficiently produce high-quality products but also ensures they stay at the forefront of the fast-paced developments in the machining industry.

Mastercam Training at Customer Facilities or with Camcut Support

Mastercam training is primarily conducted on the customer’s premises using their products or alternatively using Mastercam exercises available in the Camcut support section. By training your machine shop's CAM programming to a new level, you will effectively utilize the latest features of the software. Learn more about maximizing the efficiency of Mastercam through training.

Mastercam Training Videos for Effective Self-Study

Mastercam training videos offer an innovative way to learn the Mastercam software easily, flexibly, and efficiently.

Flexible Learning with Mastercam Training Videos

Students can learn at their own pace with clear Finnish-language instructional videos. The teaching materials include practical exercises that meet the needs of the industry and can be machined on the machines of educational institutions.

Mastercam Training Videos Free Up Teachers' Time

Teachers can focus on improving the quality of instruction and supporting students, as they do not need to create training materials themselves. Students receive a thorough overview of drawing workpieces, modeling, adjusting tolerances, as well as modern toolpaths and machining values. The material does not tie up teachers' time for actual CAM teaching, as it includes everything necessary for students to self-learn.

Content and Benefits

The exercises include ready-made 2D drawings, necessary 3D models, and example files for practical training, as well as step-by-step Finnish-language instructional videos. The training pieces are designed to meet the needs of the industry, and their programming is carried out using the latest features of the Mastercam software. In addition to programming, students learn to adjust machining values according to the requirements of various materials, tools, and machine tools.