Mastercam Mill

Mastercam Mill is the Perfect Solution for Milling

Mastercam Mill is a comprehensive software that offers powerful toolpaths for milling, drilling, and threading. The software is available in two different license levels: the traditional Mill version and the advanced Mill3D version. The traditional Mill version includes a wide range of 2D and 2.5D features as well as individual 3D surface and parallel multi-surface operations. With Mastercam Mill, users can easily create toolpaths for a variety of machining centers, including vertical and horizontal machining centers, long milling machines, gantry mills, boring mills, and multi-axis machining centers.

The Mastercam Mill version is an excellent choice for machine shops focused mainly on traditional machining, such as 2D and 2.5D machining. The software provides a comprehensive selection of tools for all needs: from leveling to profile milling, drilling, and threading. The 2D Dynamic Milling offers advanced strategies for material removal, making machining faster and more efficient than ever.

One of Mastercam Mill's most significant strengths is its ability to support the programming of various machine types. Toolpaths can be created directly on 2D or 3D geometry imported into the program, or they can be easily created with the Design features directly in Mastercam. This offers users flexibility and ease of use regardless of the job requirements.

Mastercam's Advanced Features for Milling

Thanks to the advanced dynamic toolpaths of Mastercam Mill and Mill3D, users achieve significant savings in machine time and tool life. Dynamic Milling keeps the tool's engagement angle with the material constant, which maintains the chip thickness and machining forces steady throughout the machining process. This feature makes it easier to optimize toolpaths, reduce tool wear, and significantly improve machining efficiency and quality.

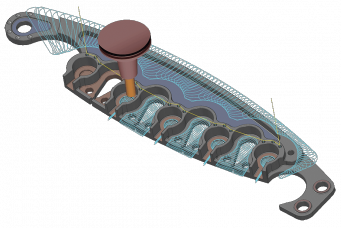

The Mill3D license provides users with even more possibilities through 3D surface milling. The 3D toolpaths, an integral part of Mill3D features, enable efficient and modern methods for machining 3D surfaces. This makes it an especially attractive option for manufacturing molds, tools, and other complex 3D parts.

As demands increase and machining requires 4- or 5-axis control, the Mill3D license can be upgraded to include Mastercam's Multiaxis add-on. These features offer complete tools for performing complex and precision-demanding multi-axis machining tasks. Multiaxis features allow for precise control of machine movements, optimizing machining efficiency and accuracy.

One of the great features of Mastercam Mill is the ability to easily utilize previously made machining operations by copying and importing them from other programs. This feature speeds up programming, reduces manual work, and increases the efficiency of work processes.

-

Mastercam Mill