Mastercam Router

Mastercam Router: A Versatile Programming Tool for Wood and Composite Machining

Mastercam Router offers extensive capabilities for machining wood or composites using 2D, 3D, and multi-axis toolpaths. This software also supports multi-spindle drilling heads and angle heads, common in various woodworking machines, helping to maximize productivity and minimize downtime caused by errors.

Mastercam Router is designed to simplify, speed up, and ensure reliable CNC programming, making it an ideal tool for any user, whether a hobbyist working at home or a professional manufacturer. With Mastercam Router, you can achieve a high-quality and secure machining process, yielding excellent results in both wood and composite materials.

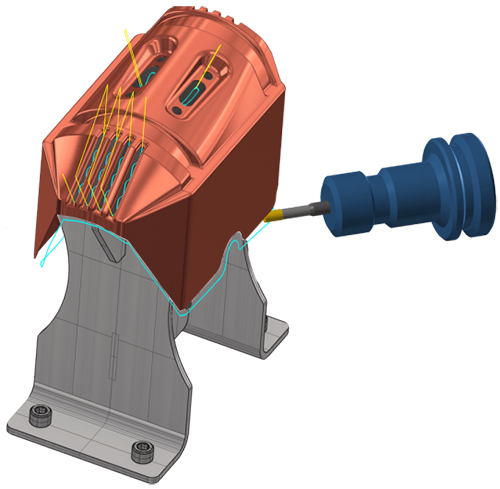

Mastercam Router supports the specific features of CNC router-type machines, such as toolpath and geometry duplication, control of drilling support, support for accessories and angle heads, saw support, and complete 2-5 axis machining capabilities. This wide range of features allows flexibility from simple 2D programming to complex 5-axis machining.

Mastercam Router offers full 3D CAD modeling, supporting programming of simple shapes, their nesting, or automatic toolpath generation (ATP). Multi-axis tool motions are efficient, and the software supports entire tool libraries as well as customized tools.

Simulation features enable collision detection with stock, tools, and machine parts before the code is sent to the machine, making the software a reliable way to verify 3-, 4-, and 5-axis toolpaths.

Mastercam Router offers standard and advanced nesting options, such as TrueShape nesting and nesting with residual materials. Users can also create beautiful signs, artistic sculptures, and molds with convenient CNC engraving features.

Dynamic Motion™ strategy maximizes material removal rates and reduces machining times, which extends tool life. The Solids Disassembly feature allows automatic disassembly of assemblies and movement of components to different levels based on part thickness.

Thanks to its versatile features, companies can diversify and remain competitive in the market. Mastercam's efficiency and rapid simulation and machining steps bring ideas to completed parts more quickly and efficiently.